10 / 11 / 13

DESIGN FOR PRINT / OUGD504STOCK OPTION & PRINT FINISHES.

STUDY TASK 3

With a focus on Stock, Substrate and 'special' Print Finishes find as many variants as possible for each of the following areas of Design

BRANDING & IDENTITY

lino-cut printing / Lumburr co.

Leather emboss / 28 HongKong street

Screen print / Own business cards

Spot Varnish / Perfume

Business cards / Lasercut

* * * *

Embossed / Waffled

Napolitain Chocolates / Foil print

The cheese shop / Screen print

Spot varnish / Juicy fruit

* * * *

EDITORIAL & PUBLICATION

Foil print / Forbury Place

Soft touch coating / bbcon 2011

OWT creative issue / Screen print

American psycho / Laser cut.

Aqueous Coating / Perceptions Literary Magazine

Emboss / Arabic Wedding invitations

Foil print / wedding invitation

UV Coating / GHA Brand alignment

Happily ever after / Laser cut

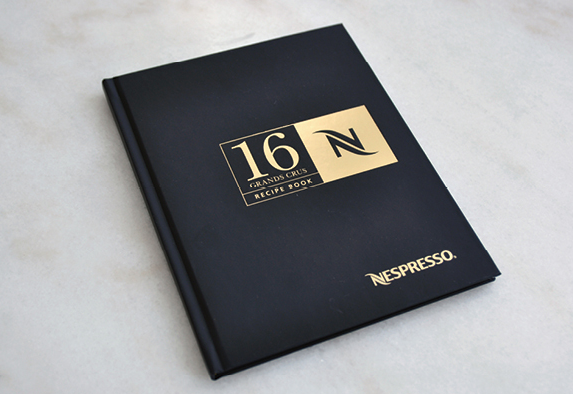

Recipe book / Soft touch coating

* * * *

COATED & UNCOATED

PAPER STOCK

Paper that are considered as coated have a smooth finishing over the suface. This is a result of a polish that is applied through the manufacturing process and the pressing of the paper. this polish makes the surface of the paper less absorbent of ink and helps to avoid bleeding of the ink through the paper. Because of this characteristic, these papers are better to use when printing work that has multiple colour such as photograph.

Uncoated paper is simply paper to which this polish has not been applied. This means that the surface of the paper seems suffer and more textured than coated. Because there is no polish acting as a barrier to prevent bleeding, printing on this type of paper means the ink will be absorbed more into the paper which can make images such as photographs look blurred. Due to this, uncoated perp is usually used for simple prints such as letter heads.

PRINT COATING

Aqueous Coating

Aqueous coating is a clear, fast-drying water-based coating that is used to protect printed pieces. It provides a high-gloss or matte surface that deters dirt and fingerprints. Aqueous coating improves the durability of postcards and other mailed pieces as they go through the mail, and protects business cards as they ride around in people's wallets. It also looks beautiful on brochures, catalog covers, and presentation folders. Aqueous coatings provide more substantial scuff-resistance than varnishes. Aqueous is typically applied to the entire printed piece, usually by the last unit on a printing press. Due to its water base, aqueous

coating is more environmentally friendly than varnish or UV coatings.

Varnish

Varnish is basically clear ink and can be gloss, satin or matte. A flood varnish covers the entire printed page for protection or sheen. A spot varnish allows you to highlight specific areas of a printed piece and adds shine and depth to specific elements on the page such as a logo or image. Varnishes are also applied on-press, but they are heavier-bodied and can be applied (like inks) to only certain areas (spot varnish). A plate must be created to apply a spot varnish, so artwork is necessary.

UV coating

UV coatings are cured by exposure to ultraviolet light to quickly dry and harden the coating. UV coatings provide the highest gloss versus other coatings but may crack when scored or folded due to the thickness and hardness of the coating. Some find it too shiny for some uses. UV coatings can be applied as a flood (covering the entire printed sheet) or as a spot coating and can be applied on or off press. UV compatible inks must be used on sheets that will be UV coated. UV coated sheets can not be foil stamped and embossing should be done after the coating.Soft Touch Coating

This coating creates a velvety texture. The paper becomes "soft" to the touch and increases the tactile appeal. It creates a softer look and feel on printed materials than either aqueous or UV coating, while creating a barrier which is fingerprint resistant. It dries fast, is non-yellowing, and is eco-friendly. Luxurious and sophisticated are words often used to describe the effect Soft Touch® coating produces.This is a process that uses a pre-cut die to stamp and cut into paper. This allows you to cut out shapes in a consistent manner over multiple pieces such as wedding invitations, greeting cards, stickers or nets for boxes. The die used can be made form multiple types of material such as plastics, lino, card and various metals. Considering what material your die should consist of is vital as you have to take into consideration on how many times this die would be used (so as not too wear it out) and also what type of design you with to have cut by the die (decorative or simple).

EXAMPLE OF A DIE CUT BUSINESS CARD.

EXAMPLE OF MASS PRODUCED DIE CUT BOX

DIE CREASING

This is simply the same process as die cutting however the pressure applied when stamping is lesser so the die does not break the surface of the material it only indents and creases the surface. This is most used for items that are required to be folded such as box nets and leaflets. In some machinery, these two process can be applied at the same time.

EXAMPLE OF DIE CREASE BUSINESS CARD

EMBOSSING

Embossing has the same principle as die cutting and creasing. Rather than the die stamping for the use of a fold, it is stamped as a decorative feature that raises (embosses) the surface of the paper so it stands hight than the original surface or it deepens (de-bosses) the surface of the paper so it stands below the original surface.

DUPLEX PRINTING

This is simply when a printer has the capabilities of ringing on both side of a piece of paper at the same time.

LAMINATE

Lamination is when a clear plastic film is applied to the surface as a finish and is used as a type of protections to the original material. It is a permanent application that is applies by as press or heat.

No comments:

Post a Comment